The Role of UV Polarizing Inks in Anti-Counterfeiting Solutions

Silk pringting polarizing inks are integral to modern security printing, serving as a powerful anti-counterfeiting tool. These inks, designed to polarize light under ultraviolet (الأشعة فوق البنفسجية) conditions, create intricate patterns that are almost invisible to the naked eye but become visible when exposed to UV light. This unique property makes them an essential element in packaging, وثائق, and banknotes, ensuring authenticity and preventing unauthorized reproduction.

While the effectiveness of polarizing inks is undeniable, their performance can be influenced by various environmental factors. في هذه المقالة, we explore the key factors that impact the performance of UV polarizing inks, the role of these inks in anti-counterfeiting applications, and how they adapt to different environmental conditions.

Section 1: Understanding UV Polarizing Inks

Before delving into the factors that affect silk printing polarizing inks, it’s essential to understand their composition and function.

What Are UV Polarizing Inks?

The inks are specialized inks that incorporate polarizing agents, which interact with UV light to create hidden patterns. These inks work by altering the polarization of light passing through them, making certain designs visible only under specific lighting conditions.

How Do UV Polarizing Inks Work?

These inks contain molecules that react to UV light, creating an effect invisible under normal conditions. This feature is crucial for anti-counterfeiting, where markings or designs are visible only under specific circumstances, ensuring authenticity.

Section 2: Environmental Factors Affecting UV Polarizing Ink Performance

Section 2: Environmental Factors Affecting UV Polarizing Ink Performance

Several environmental conditions can influence the functionality of UV polarizing inks. These factors need to be carefully considered during the manufacturing and application of such inks in anti-counterfeiting measures.

1. Temperature Variations

Temperature fluctuations significantly impact UV polarizing inks. Extreme heat or cold can alter their physical properties, reducing efficiency or causing permanent damage to polarization effects.

-

High temperatures can degrade the ink’s ability to polarize light effectively. This occurs when the molecular structure of the polarizing agents breaks down. نتيجة ل, the ink may become less visible or even invisible under UV light.

-

على الجانب الآخر, extremely low temperatures can make the ink brittle, causing it to crack or peel. This compromises the security features and reduces their effectiveness.

لذلك, testing UV polarizing inks across various temperatures during development is crucial. This ensures they perform consistently under typical environmental conditions.

2. Humidity and Moisture Exposure

Moisture is another environmental factor that can significantly affect the performance of UV polarizing inks. High humidity or exposure to water can cause the inks to lose their adhesive properties or undergo chemical reactions that alter their ability to polarize light.

-

Moisture Absorption: Inks can absorb moisture from the air, which can lead to a change in their optical properties. This makes them less effective in revealing hidden patterns under UV light.

-

Water Exposure: Prolonged exposure to water can cause the ink to wash away or become smudged, leading to irreversible damage to the security features.

Manufacturers must consider humidity resistance when producing UV polarizing inks, especially for products that will be exposed to variable or harsh climates.

3. UV Light Intensity

The very essence of UV polarizing ink performance relies on ultraviolet light. The intensity and quality of the UV light can play a critical role in the visibility and clarity of the polarizing effects.

-

High UV Exposure: Extended exposure to intense UV light can cause the ink to degrade over time. This degradation may result in the loss of polarization ability, affecting the long-term effectiveness of the security features.

-

Insufficient UV Light: بصورة مماثلة, insufficient exposure to UV light can make the markings less visible, rendering them ineffective as a security feature. Ensuring the right type of UV light intensity is crucial for optimal performance.

This is particularly relevant in environments where UV light levels vary, such as in outdoor settings versus controlled environments like retail spaces or warehouses.

4. Surface Type and Ink Adhesion

The surface to which the UV polarizing ink is applied plays a significant role in determining its performance. مواد مختلفة, مثل الورق, البلاستيك, معدن, أو النسيج, interact with ink in unique ways, affecting adhesion and the final visual result.

-

Surface Roughness: A rough surface can lead to uneven ink distribution, which can cause the polarized effect to appear inconsistent. On smooth surfaces, ink is more likely to be evenly spread, leading to a more reliable and consistent effect.

-

Surface Material: Certain materials, like plastics or glossy finishes, can interfere with the light-polarizing ability of the ink. These materials may cause light refraction, impacting the clarity and effectiveness of the ink’s security properties.

Choosing the right substrate for UV polarizing inks is crucial for ensuring that the security features remain intact over time and under various handling conditions.

5. Chemical Exposure

UV polarizing inks can also be affected by exposure to certain chemicals or solvents, especially those found in cleaning agents or environmental pollutants.

-

Chemical Interaction: Some chemicals may cause the ink to react, either degrading the ink’s polarization or causing it to fade over time. على سبيل المثال, solvents or oils can break down the binding agents in the ink, resulting in smudging or complete loss of the effect.

-

Pollutants: Outdoor environments with high levels of air pollution or chemicals can accelerate the breakdown of polarizing inks, reducing their effectiveness as a long-term anti-counterfeit solution.

Preventing such interactions involves ensuring that UV polarizing inks are formulated to be resistant to common environmental pollutants and chemicals.

خاتمة: The Future of UV Polarizing Inks

As UV polarizing inks continue to evolve, so too will their applications in the fight against counterfeiting. لكن, understanding and mitigating the environmental factors that impact their performance is crucial to ensuring long-term reliability and effectiveness. By prioritizing ink formulation, testing, and environmental considerations, manufacturers can ensure that their silk printing polarizing inks remain a trusted tool in the battle against counterfeit goods, وثائق, والتعبئة.

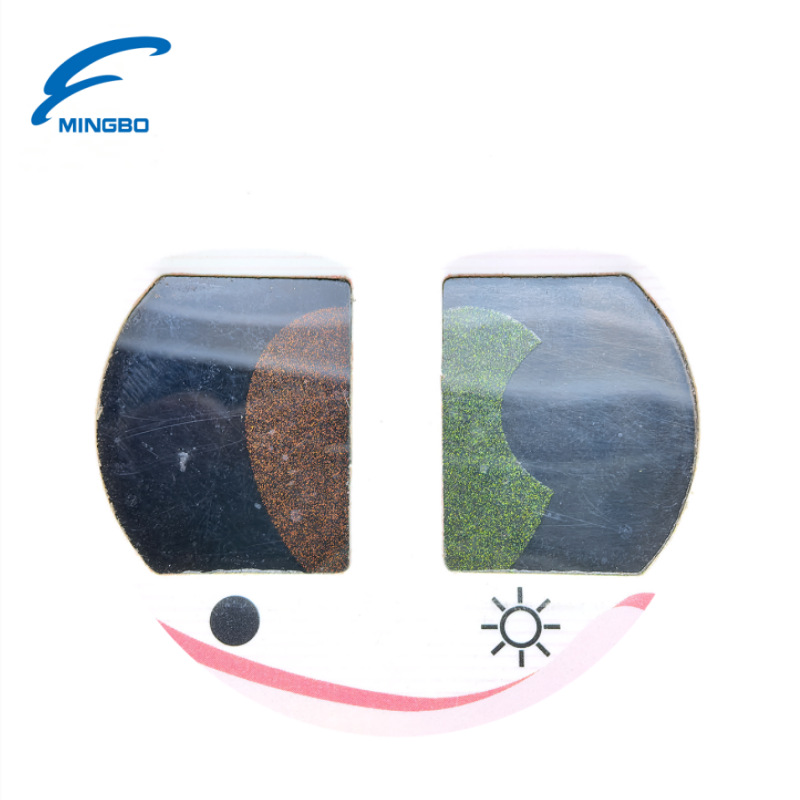

دعوة إلى العمل: [Learn more about Mingbo’s UV Polarizing Inks for Anti-Counterfeiting Solutions]