In the race to stay ahead of counterfeiting, traditional print technologies are no longer enough. As forgers grow increasingly sophisticated, industries must adopt smarter, invisible methods of authentication. Among the most promising breakthroughs is meta-material IR ink—a disruptive technology that blends the science of nanostructures with covert spectral behavior.

These next-generation inks use engineered meta-material structures to create IR security labels that appear identical to the naked eye, yet behave uniquely under infrared (IR) light. This dual-behavior effect is setting a new standard in anti-counterfeit design across sectors from pharmaceuticals to electronics.

What Are Meta-Material IR Inks?

Meta-materials are artificially structured materials designed to exhibit electromagnetic properties not found in nature. When applied to ink systems, these materials manipulate how light behaves—especially outside the visible spectrum.

Meta-material IR inks are engineered so that their pigment structure reflects visible light in a specific way, giving the illusion of identical colors across different labels. However, under infrared illumination, these inks reveal selective absorption or complete transparency. This shift from visible mimicry to IR failure forms the foundation of their security function.

In simpler terms, these inks can make two packages look the same to the human eye, but appear completely different under IR verification systems.

Why Meta-Material Inks Matter for Security Printing

Modern counterfeiting techniques exploit digital replication, color matching, and substrate duplication. Traditional UV or holographic features can be scanned or mimicked with relative ease. In contrast, meta material anti-counterfeit technology introduces an invisible layer of protection that’s nearly impossible to reproduce without specialized knowledge and materials.

This level of security stems from physical structuring at the nano or micro scale, which cannot be reverse-engineered through visual or chemical analysis alone. Moreover, the non-linear behavior of these materials under IR adds another verification tier—one that’s invisible, yet machine-verifiable.

The Principle of Spectral Coherence and IR Failures

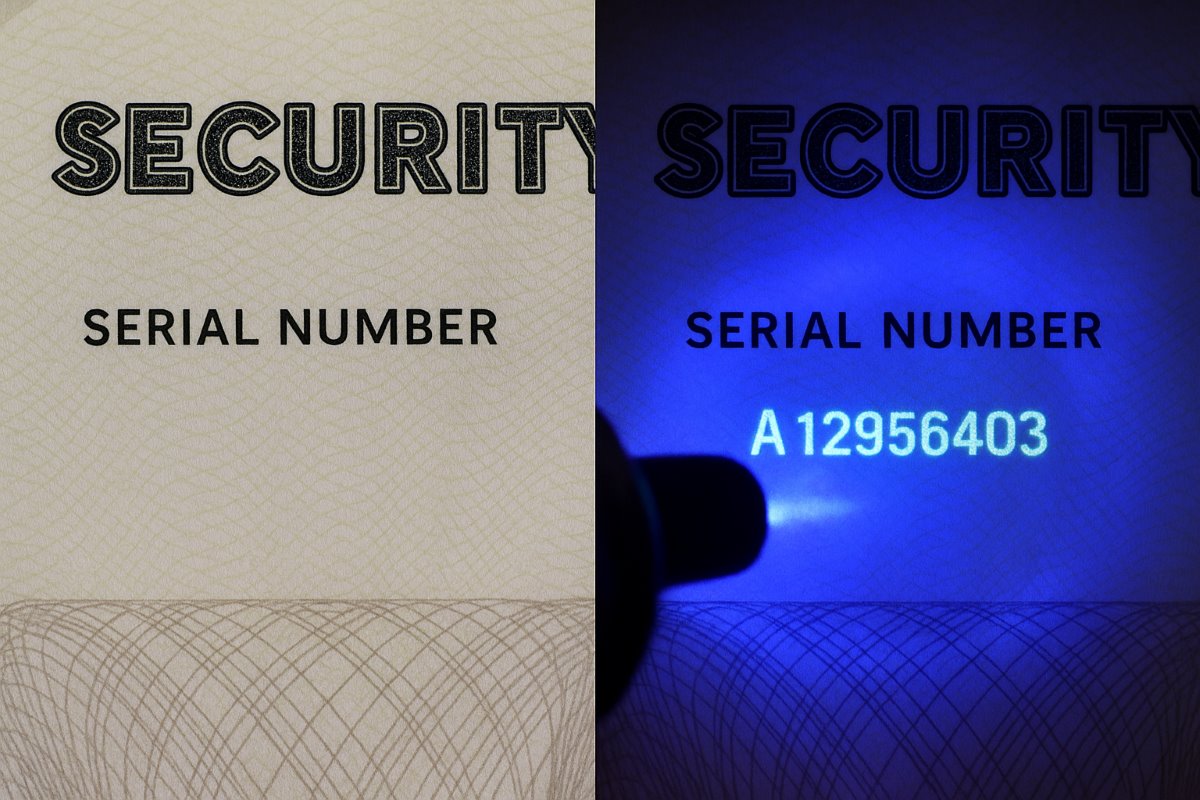

The genius of IR-transparent inks lies in their ability to remain spectrally coherent in the visible spectrum while intentionally “failing” in the IR range. Unlike conventional IR-visible dual-mode inks, meta-material inks provide one-way coherence. This means:

-

Under daylight or LED, the ink looks identical to standard inks.

-

Under IR cameras or sensors, the pigment disappears or changes tone.

This predictable failure under IR allows brand owners to embed digital markers, hidden codes, or IR-invisible QR identifiers without altering the visible design. Security is hidden in plain sight.

Applications Across High-Risk Industries

Several industries are now deploying meta-material IR inks to protect products, documents, and packaging.

Pharmaceuticals

Drug packaging faces persistent threats from counterfeit medications. Meta-material inks offer discreet yet robust verification. Pharmacists or regulators can use IR handheld devices to verify the ink’s response—no network connection required.

Luxury Goods and Fashion

Counterfeit luxury goods damage both brand equity and revenue. By embedding IR security labels into hang tags or labels, designers maintain clean aesthetics while integrating unforgeable product markers.

Government Documents and Tax Stamps

Customs, immigration, and excise authorities rely heavily on tamper-evident materials. Meta-material-based printing allows invisible serial validation without introducing visually complex features, which may confuse users.

Consumer Electronics

The electronics sector is plagued by counterfeit accessories and batteries. Infrared-checkable brand labels ensure authenticity across decentralized supply chains.

Artwork and Certificates

Certificates of authenticity, limited edition prints, and museum labeling systems increasingly benefit from meta-material ink, which ensures legitimacy without visual distractions.

Design Freedom with Functional Invisibility

A hallmark of meta-material IR ink is its design neutrality. Designers are no longer forced to accommodate bulky or obvious security features like holograms, foil, or overt color shifts. Instead, meta-material inks blend seamlessly into existing graphic layouts.

Because these inks are formulated to match conventional CMYK or spot colors under standard lighting, they allow branding and visual storytelling to remain pure. This is particularly valuable in premium and minimalist packaging, where discretion is key.

Simultaneously, the covert IR behavior adds security that can be verified across any supply chain step—without revealing secrets to counterfeiters.

How IR Transparent Inks Are Manufactured

Creating IR-transparent inks requires precision engineering. At Mingbo, we blend nanostructured pigments into carrier systems optimized for specific substrates—paper, plastic, foil, or fabric.

Each formulation is tuned to:

-

Achieve spectral matching in the visible range

-

Exhibit defined behavior under IR-A, IR-B, or IR-C bands

-

Maintain print stability and adhesion across production temperatures

-

Prevent migration, bleeding, or degradation over time

We conduct real-time stability testing under various humidity, light, and handling conditions to ensure long-term reliability. This ensures our clients receive inks that are not only smart but also stable and compliant.

Integration with Digital and Physical Authentication

The most advanced IR security labels integrate with both analog and digital verification systems. While human inspection can catch IR mismatches using readers, automated platforms can scan large volumes of packages via IR cameras on conveyors or customs lines.

Furthermore, these inks can be layered with RFID, NFC, or blockchain triggers. For example, a product may scan correctly on IR but only match a blockchain hash if genuine. This multilayer approach enhances both physical and digital traceability.

We call this hybrid authentication—a future-forward method where every link of the supply chain contributes to verification without increasing consumer friction.

Overcoming Counterfeit Adaptation with Dynamic Features

The challenge with any anti-counterfeit technology is staying ahead of copycats. With meta-material anti-counterfeit systems, the advantage lies in complexity and variability.

Mingbo offers programmable variability in pigment orientation, substrate interaction, and spectral tuning. This makes each ink batch unique to its purpose. Counterfeiters, even with samples, cannot replicate the structural arrangement or behavior without knowing the exact design blueprint.

Our ink systems also allow multi-wavelength responsiveness—inks that fail under one IR band but pass under another, adding deeper verification layers.

Global Adoption and Future Market Outlook

Global Adoption and Future Market Outlook

While meta-material ink is still considered emerging, adoption is accelerating. Regulatory bodies in the EU and Asia have begun pilot programs for IR-sensitive excise stamps. Multinational pharma companies now specify meta-material-based security in new packaging RFQs.

According to industry forecasts, the IR transparent inks market is expected to grow at a CAGR of over 18% over the next five years. This rise reflects not just demand, but confidence in the underlying science.

Mingbo is currently expanding its R&D and global licensing network to meet growing demand. Through strategic partnerships with printing presses, labeling firms, and supply chain managers, we ensure secure implementation across continents.

Conclusion: Seeing the Future Through Invisible Ink

Security in the modern age is not just about stopping counterfeiters—it’s about staying invisible, seamless, and resilient. Meta-material IR inks represent a generational leap in this pursuit. By combining scientific innovation with functional design, these inks allow industries to protect assets, reputations, and consumers in ways never before possible.

At Mingbo, we are not just ink suppliers—we are architects of trust. Every drop of our ink carries structural intelligence, optical behavior, and covert confidence. As the world demands smarter packaging and verifiable identity, we deliver clarity through invisibility.

The future of anti-counterfeit is not loud. It is silent, smart, and spectral—and it’s already here.