Temperature Integrity in a Sensitive Supply Chain

In the realm of cold chain logistics, temperature control is everything. From life-saving vaccines to delicate food products, temperature-sensitive goods must stay within strict parameters. Any deviation can compromise safety, quality, and regulatory compliance. This reality has driven the development of innovative visual indicators. Among them, thermochromic labels have emerged as powerful tools for real-time temperature monitoring.

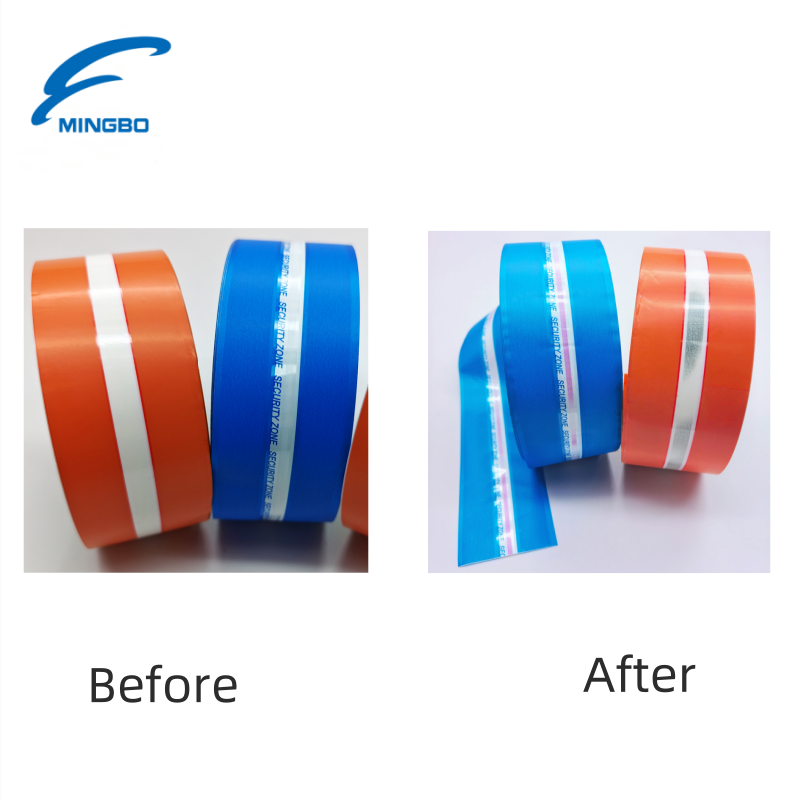

Thermochromic printing inks, which change color with temperature fluctuations, are the foundation of these labels. For cold chain stakeholders, these color-shifting labels offer immediate visual feedback.

Understanding Thermochromic Printing Inks: The Science Behind the Color Shift

Thermochromic inks are formulated with leuco dyes or liquid crystals that alter their molecular structure with temperature changes. This structural shift affects how the material absorbs and reflects light, causing a visible color change. These changes are reversible or irreversible, depending on the ink formulation.

In cold chain logistics, irreversible thermochromic inks are often preferred. They provide a clear, tamper-proof visual record that an item has exceeded a specified temperature threshold. The simplicity of a color change allows for universal interpretation, requiring no special equipment.

Furthermore, these inks are versatile. They can be applied to adhesive labels, shrink sleeves, carton surfaces, and direct product packaging. Their stability under extreme conditions makes them reliable even in deep-frozen environments.

Cold Chain Compliance and Visual Verification: Why Thermochromic Labels Matter

Maintaining temperature consistency throughout transport and storage is a regulatory imperative. Guidelines from authorities such as the WHO and FDA demand robust monitoring systems. Traditional electronic sensors provide precise data, but they come with higher costs and limited visual accessibility. This is where thermochromic labels shine.

They offer instant, easy-to-read indicators that show if a product has been exposed to non-compliant temperatures. For frontline workers, warehouse staff, and consumers, these visual cues enhance transparency and accountability. When a color shift occurs, it serves as both an alert and a traceable compliance measure.

Thermochromic labels also reduce training needs. Users do not require specialized knowledge to interpret the result. Consequently, they lower operational costs and minimize errors in fast-moving logistics environments.

Applications Across Industries: Where Thermochromic Labels Excel

The utility of thermochromic printing inks spans multiple industries within the cold chain.

Pharmaceutical Logistics: In vaccine distribution, even slight temperature excursions can lead to loss of efficacy. Thermochromic labels enable rapid inspection during loading, delivery, and unpacking. They offer assurance to healthcare professionals and regulators.

Perishable Foods: In the seafood, dairy, and meat sectors, freshness and safety depend on temperature. Thermochromic indicators on cartons and pouches provide real-time visibility to retailers and consumers alike.

Biological Samples and Lab Materials: In research and diagnostics, thermochromic labeling ensures that test kits and cultures remain within controlled ranges. This is crucial for accurate results and biosecurity.

Cosmetics and Chemicals: Certain active compounds degrade with heat. Thermochromic inks on primary or secondary packaging ensure these products reach consumers in optimal condition.

Design and Integration: Creating Functional Thermochromic Labels

Effective thermochromic labels require careful design. Factors such as activation temperature, duration sensitivity, and visibility all affect performance. Mingbo collaborates with clients to develop labels tailored to their supply chains.

Design considerations include:

- Activation Temperature: Customizable from -20°C to +70°C based on product needs.

- Color Contrast: High-contrast transitions improve visibility and readability.

- Print Compatibility: Inks must bond effectively with substrates like paper, PET, or BOPP.

- Lifespan and Shelf Stability: Extended ink stability is critical for long distribution cycles.

Integration into existing packaging lines is seamless with Mingbo’s ink formulations. Our inks support flexographic, gravure, and screen printing, ensuring efficient production.

Challenges and Considerations in Real-World Use

Challenges and Considerations in Real-World Use

While thermochromic labels offer numerous benefits, certain factors must be addressed:

- Exposure to UV and Humidity: Protective coatings can preserve label integrity.

- Temperature Reversibility: Some applications may require irreversible color changes.

- False Activation Risk: Labels should avoid premature shifts during handling.

- Regulatory Certification: Compliance with FDA and EU ink safety standards is essential.

Mingbo conducts rigorous testing to ensure our thermochromic inks meet industry-specific requirements. Every batch is inspected for consistency, activation accuracy, and adhesion.

Conclusion: The Future of Smart Cold Chain Packaging

Thermochromic printing inks have transformed how cold chain logistics monitors temperature compliance. As global supply chains become more complex, visual verification will play an even larger role. From pharmaceuticals to perishables, the demand for cost-effective, reliable, and intuitive indicators will grow.

Mingbo leads this transformation. With customizable thermochromic inks and deep technical expertise, we empower industries to protect their products and build trust. Thermochromic labels are not merely optional; they are essential tools in the quest for cold chain integrity.

CTA: [Partner with Mingbo for Advanced Thermochromic Ink Solutions]